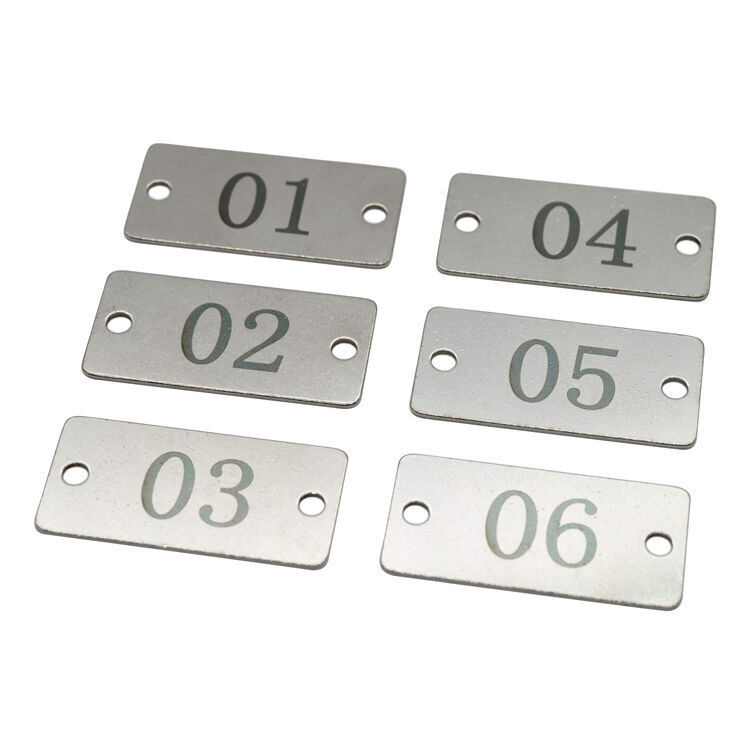

Product Information

| Model Number | metal labels | ||||

|---|---|---|---|---|---|

| Brand Name | Alwells | ||||

| origin | China | ||||

| Small Orders | Accepted | ||||

Key Specifications/ Special Features:

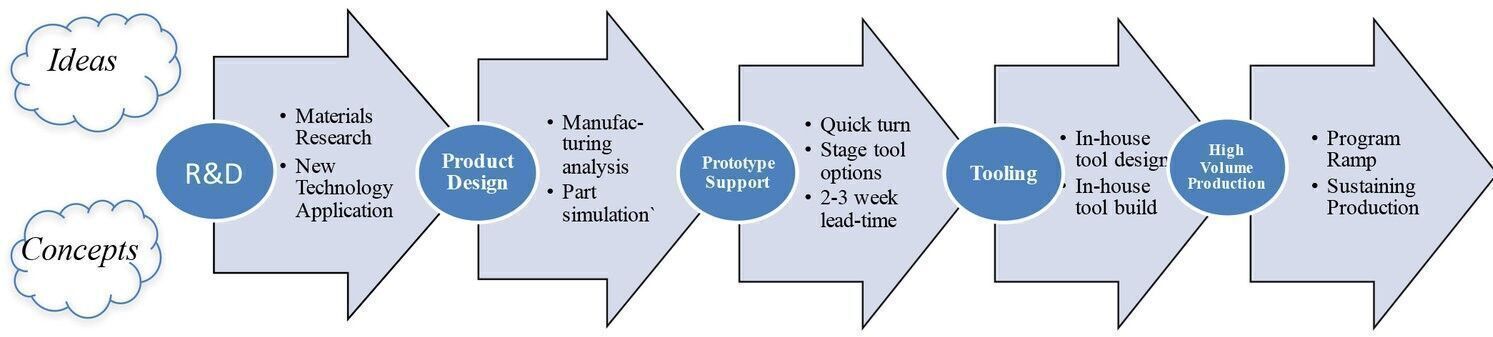

The manufacture of cutting and trimming dies with different profiles is carried on high precision grinding centres, high-speed machining centres, wire and electrode EDM and CNC lathes for hard lathing (steel and carbide) based on TEMSA’s technology. The technical department will help selecting the most suitable steel or carbide tool for the material to be cut.

A young and expert team, using state-of-the-art CAD-CAM software, such as POWERMILL, MASTERCAM, FIKUS & SIMCT, supported by modern simulation software, will develop the necessary programs that make possible generating the requested profiles.

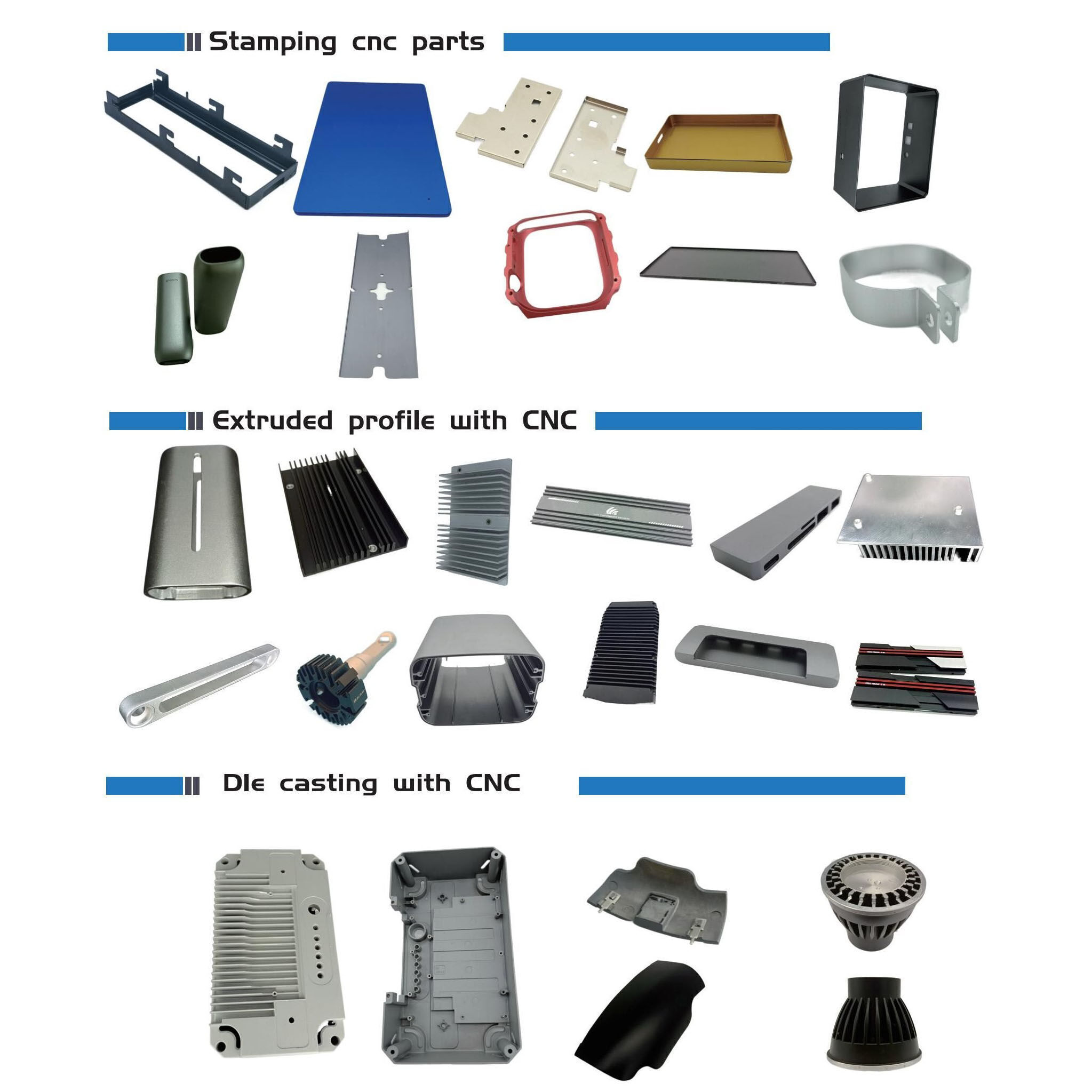

| Product | Metal stamping part metal Forging part metal Casting part

Tooling Flame cutting Laser cutting CNC machining Assembly Polish Coating CNC turning CNC milling Drilling Grinding Wire-EDM Cutting Die Casting Extrusion |

| Cutting-edge Equipment List | Panasonic OTC welding robot Amada electro hydraulic synchronous CNC bending machine Mazak CNC 3 axes machining machineTruLaser 3040 12000w Laser Cutting Machine |

| Material | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper Titanium: Grade F1-F5 Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. |

| Surface Roughness | Min Ra 0.1~3.2 |

| Quality control | ISO 9001:2008, factory audited by Bureau Veritas |

| Tolerance | +/-0.5~1.5mm |

| Surface Treatment | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| Quality Assurance | ISO9001:2015, ISO13485:2016, SGS, RoHs, TUV |

| Export Percentage | 100% |

| Sample time | 7 -14 days |

| Main market | North and South America, Europe, Oceania |

China OEM ODM factory cnc machined part Rapid Prototyping Custom CNC Milling Plastic Parts Machine spare parts hardware auto part stamping part bike motorcycle boat electronic component hinge

Established in 2001, Alwells Industry is an integrated company engaged in both manufacturing and trading. Alwells mainly focuses on the customization of metal products and metal parts.

We makes a wide range of production processes i.e. metal stamping, laser cutting, sheet metal bending, metal welding, metal machining and metal surface treatment.

After 20 years of development, we now have 70 employees and a factory covering an area of 20,000 square meters. With state-of-art machines for stamping, laser cutting, bending, forming, welding, machining, assemby, our factory has developed into a well-equipped and modern factory with standardised production.

We currently has 3 stamping production lines, 4 laser cutting production lines, 4 bending production lines, 6 automatic welding production lines, 4 machining production lines and 3 assembly production lines. All the machines are purchased from well-known brands in Germany and Japan, including Lasco, Amada, Mazak, Panasonic and so on.

Over the past 15 years, our company has made efforts to expand overseas markets. We have an experienced export business team. Our customers are from more than 30 countries and regions such as Europe, North America, and Australia.

Our products are applied to different fields include aviation, rail transit, mechanical equipment, telecommunication, medical equipment, energy, automobiles and motorcycles etc.

Besides customized hardware, we also provide all kinds of trolleys and carts used in aircafts, high-speed trains and hotels.

China OEM ODM factory cnc machined part Rapid Prototyping Custom CNC Milling Plastic Parts Machine spare parts hardware auto part stamping part bike motorcycle boat electronic component hinge

Shipping Information

| FOB Port | Qingdao | ||||

|---|---|---|---|---|---|

| Weight per Unit | 100.0 Grams | ||||

| HTS Code | 7326.00.00 00 | ||||

| Export Carton Dimensions L/W/H | 100.0 x 100.0 x 100.0 Centimeters | ||||

| Logistics attributes | Common | ||||

| Lead Time | 30–60 days | ||||

|---|---|---|---|---|---|

| Dimensions per Unit | 10.0 x 10.0 x 10.0 Centimeters | ||||

| Units per Export Carton | 1000.0 | ||||

| Export Carton Weight | 1.0 Kilograms | ||||

Reviews

There are no reviews yet.